- PARALLEL PORT CNC CONTROL ALGORITHM C HOW TO

- PARALLEL PORT CNC CONTROL ALGORITHM C SERIAL

- PARALLEL PORT CNC CONTROL ALGORITHM C DRIVER

- PARALLEL PORT CNC CONTROL ALGORITHM C FULL

- PARALLEL PORT CNC CONTROL ALGORITHM C CODE

NEW Super Smooth Stepper Algorithm: Complete overhaul of the handling of the stepper driver to simplify and reduce task time per ISR tick. And your settings will be over-written! Make sure to have a backup.

PARALLEL PORT CNC CONTROL ALGORITHM C SERIAL

IMPORTANT: Default serial baudrate is now 115200! (Up from 9600). See our Configuring v0.9 Wiki page for details. Also, settings have been renumbered and some have changed how they work.

aka The Originator/Creator/Pioneer/Father of Grbl. Lead Developer : Simen Svale Skogsrud (Norway).

PARALLEL PORT CNC CONTROL ALGORITHM C CODE

This will ensure Grbl will always be an open-source project while making the code permissive for others.įor more information and help, check out our Wiki pages! If you find that the information is out-dated, please to help us keep it updated by editing it or notifying our community! Thanks! Obsolete versions of Grbl, v0.8 and prior, are released under the permissive MIT-license. Licensing: Grbl v0.9 is free software, released under the GPLv3 license. That means the controller will look up to 18 motions into the future and plan its velocities ahead to deliver smooth acceleration and jerk-free cornering.

PARALLEL PORT CNC CONTROL ALGORITHM C FULL

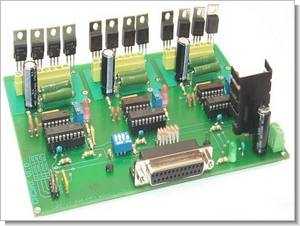

Grbl includes full acceleration management with look ahead. Macro functions, variables, and most canned cycles are not supported, but we think GUIs can do a much better job at translating them into straight g-code anyhow. Arcs, circles and helical motion are fully supported, as well as, all other primary g-code commands. It accepts standards-compliant g-code and has been tested with the output of several CAM tools with no problems. It is able to maintain up to 30kHz of stable, jitter free control pulses. The controller is written in highly optimized C utilizing every clever feature of the AVR-chips to achieve precise timing and asynchronous operation. It will run on a vanilla Arduino (Duemillanove/Uno) as long as it sports an Atmega 328. Grbl is a no-compromise, high performance, low cost alternative to parallel-port-based motion control for CNC milling. #Grbl - An embedded g-code interpreter and motion-controller for the Arduino/AVR328 microcontroller Min switches remaped to the same position in RAMPSĬheck this folder for additional documentation regarding Sanguinololu boards. Steppers redirected to fastio.h from marlin firmware Spindle direction: Extruder direction pin pin 20 is labeled as Z-STOP (connect the probe wires here) pin 18 is labeled as X-STOP (endstop) in Sanguinololu

PARALLEL PORT CNC CONTROL ALGORITHM C HOW TO

(Tested with version 1.6.5 of the Arduino IDE, 29/Sep/2015) How to connect the XYZ motors, XY endstops and Z probe Success!! :-) Click here for a GRBL/bCNC usage tutorial If you need to change any hard-coded values here, make sure to uncomment the line settings.c:301 so GRBL re-loads the defaults every time.įinally, once you have selected the correct board and USB port, you can click "Upload" to flash the GRBL firmware. IMPORTANT NOTE: When configuring your own parameters, note that GRBL stores every setting into the EEPROM in the first boot and always uses those. Next, if you want to modify any default parameters, do so in " defaults.h" (end of the file, below DEFAULTS_MPCNC). Ignore the rest of this page instead follow the official installation instructions.

Modified again by Carlosgs to support RAMPS and Sanguinololu without any re-wiring (i.e. By ArSi my mschrock to change default setting to work with Mostly Printed CNC with Mega 2560 and DRV8825 set in 1/32nd step mode.

0 kommentar(er)

0 kommentar(er)